Details

EYE TO EYE SHACKLE SPRING DIY SINGLE AXLE TRAILER KIT

INCLUDING LED LIGHTS, WHEELS AND TYRES.

AXLE LENGTHS 77" - 96"

STUD PATTERNS AVAILABLE

FORD (5/114.3 PCD, 1/2" STUDS AND NUTS)

HQ (5/120.65 PCD, 7/16" STUDS AND NUTS)

HT (5/108 PCD, 7/16" STUDS AND NUTS)

6 STUD L/C (6/139.7 PCD, 1/2" STUDS AND NUTS) +$20

IN THIS KIT

1X 40MM SQUARE BARE AXLE, 77", 79", 81", 83",85", 87", 89", 91", 93", 94", 96" ( TIP TO TIP) ( IF YOUR NOT SURE ON THE SIZE YOU NEED THEN SEND US A MESSAGE WITH YOUR CHASSIS WIDTH AND WHEELS YOUR USING IN WHICH WE WILL GIVE OUR JUDGEMENT)

2X 5 LEAF 60MM BLACK EYE TO EYE SPRINGS. RATED 1380KG PER PAIR (SPRINGS ARE SHOT PEENED FOR EXTRA STRENGTH)

2X FRONT HANGERS WITH SPRING BOLTS

2X REAR SHACKLE EXTRA STRENGTHENED HANGERS

2X HIGH TENSILE REAR DOUBLE GREASABLE SHACKLE BOLTS WITH NYLOC NUTS

2X FISH PLATES

4X 40MM X 130MM 1/2" U BOLTS WITH SPRING WASHERS AND NUTS

2X AXLE PADS

2X 5 STUD HUBS WITH CUPS ALREADY PRESSED IN. S.G CASTING (much stronger than grey iron)

2X LM HOLDEN BEARING SETS (2X LM INNER BEARINGS, 2X LM OUTER BEARINGS, 2X WASHERS, 2X SPLIT PINS, 2X DUST SEALS, 2X DUST CAPS)

1X 50MM 2000KG UNIVERSAL BALL COUPLING

1X WELD ON COUPLING BASE PLATE

3X HIGH TENSILE COUPLING BOLTS WITH NYLOC NUTS

1X PAIR LED REAR COMBINATION LIGHTS

1X LED NUMBER PLATE LIGHT

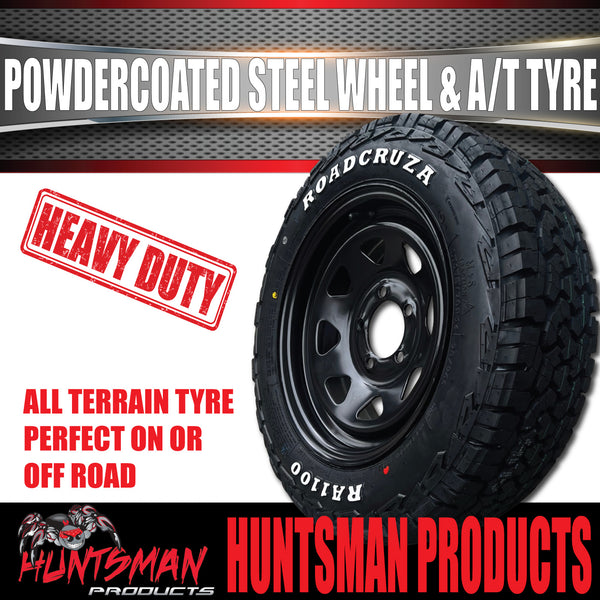

2X14" BLACK OR WHITE SUNRAYSIA STEEL RIMS WITH 185R14C (PLEASE ADVISE PREFERRED COLOUR)

ON PURCHASING PLEASE PROVIDE YOUR AXLE LENGTH AND STUD PATTERN

EXTRAS AVAILABLE

2" OR 4" DROP AXLES $295. DROP AXLES APPROX 5 DAYS TO ENGINEER

JAPANESE MANUFACTURED BEARINGS $50 (CLICK ON LINK BELOW)

"CLICK HERE TO UPGRADE TO JAPANESE MANUFACTURED BEARINGS"

(please note trailers over 750kg need brakes to legally register to 1000kg. this kits components capacity is 1000kg)

SHOT PEENING

Shot peening is a cold working process used to produce a compressive residual stress layer and modify mechanical properties of metals and composites. It entails impacting a surface with shot with force sufficient to create plastic deformation. Shot peening is often called for in aircraft repairs to relieve tensile stresses built up in the grinding process and replace them with beneficial compressive stresses.