Details

6 LEAF HEAVY DUTY GALVANISED ROCKER ROLLER TANDEM SPRING SET.

3000KG RATED

SHOT PEENED SPRINGS

Please compare the difference of Huntsman Products rocker rollers to competitors. All our roller bushes are steel and not plastic that simply disintegrate. Our steel and finish (Shot Peening) give us on average 500kg higher rating by not using cheaper lower quality sources. All our spring bolts (roller and eye) come high tensile and are greasable.

FULL KIT INCLUDES

4X 60MM X 7MM 6 LEAF DACROMET ROCKER ROLLER SPRINGS (SPRINGS ARE SHOT PEENED FOR EXTRA STRENGTH)

2X FRONT 60X8MM HANGERS NATURAL FINISH

2X REAR 60X8MM HANGERS NATURAL FINISH

2X CENTRE 50X8MM HANGERS NATURAL FINISH

2X DACROMET CENTRE ROCKER ARMS

4X SOLID STEEL 5/8” BUSHES

6X 5/8” GREASABLE SHACKLE PINS AND NYLOC NUTS

2X ¾” GREASABLE CENTRE SHACKLE PINS WITH CASTLE NUTS AND SPLIT PINS

FULL ROCKER ROLLER SET WILL COME ASSEMBLED

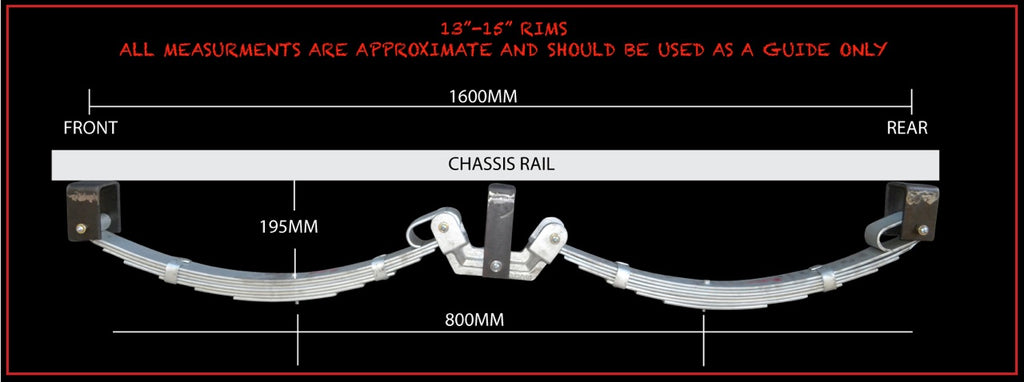

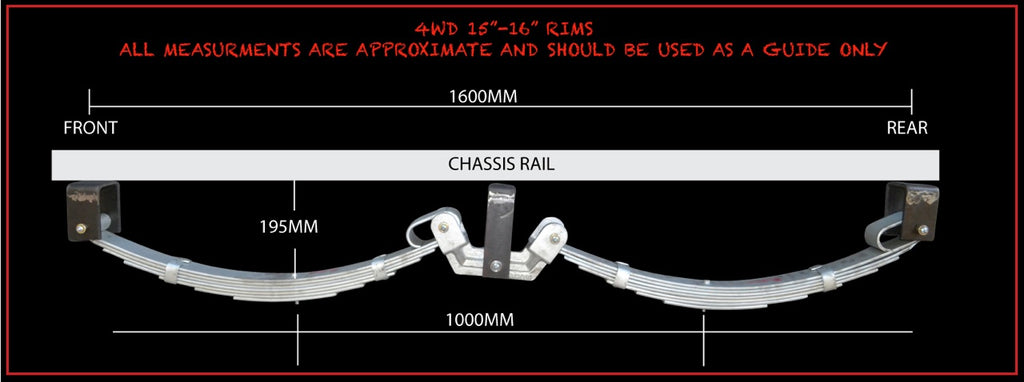

On ordering please specify whether the springs are suited to 14" wheels or 15/16" off road wheels (pictures sizing in main pictures)

If required swapping the front springs to the rear will change the offset of the springs

Please note: Quickest and most hassle free freight occurs when a commercial business address is provided

DACROMET®

DACROMET®, is the leading inorganic coating commonly specified in the wind turbine, heavy truck, marine, agricultural, construction equipment and aerospace industries. A water-based, VOC-compliant coating, DACROMET® is comprised mainly of overlapping zinc and aluminum flake in an inorganic binder.

SHOT PEENING

Shot peening is a cold working process used to produce a compressive residual stress layer and modify mechanical properties of metals and composites. It entails impacting a surface with shot with force sufficient to create plastic deformation. Shot peening is often called for in aircraft repairs to relieve tensile stresses built up in the grinding process and replace them with beneficial compressive stresses.